The primary AXES of a press brake are X, Y, Z, and R. These axes might be controlled both numerically or manually via the operator, depending on the distinct press brake configuration and abilities.

When the bends are near to the end, it could possibly tear or crack because of excessive strain. To stay away from this, use reliefs, which include small cutouts and notches at the start and end of the line.

By contrast, if you click a Microsoft-furnished advert that appears on DuckDuckGo, Microsoft Advertising and marketing would not associate your advertisement-simply click habits which has a user profile. Furthermore, it will not retail outlet or share that info aside from for accounting purposes.

The Tool Set up Optimizer selection checks which components you require a similar tools for And exactly how the tool stations might be very best put together. This enables you to bend the maximum quantity of elements with only one tool set up.

Make sure your file is within the appropriate structure, and all GD&Ts are made. Up coming, the bend line indicator is an important factor in communicating the design between engineers and experts.

How can suppliers guarantee precision and performance in sheet metal bending? Deciding upon in Visit this page between a press brake in addition to a CNC folder is critical. This short article compares their Doing the job rules, bending precision,…

Neutral Axis: The imaginary line while in the sheet metal that doesn’t stretch or compress though exerting the pressure.

Metal Supermarkets is the world’s largest modest-quantity metal supplier with about a hundred twenty five brick-and-mortar stores over the US, copyright, and Uk. We are metal specialists and have already been supplying good quality customer support and solutions given that 1985.

When selecting a goniometer for press brake programs, factors for example measurement range, resolution, and magnetic strength must be deemed to be certain compatibility with the particular bending jobs and dealing surroundings.

K aspect also provides an strategy about the fabric stretched and expanded within and outdoors of your bend. For that reason, it is actually important to determine the flat size-linked design parameters.

Study solution qualities and technical technical specs for big brands

In conclusion, no matter whether often called a “Brake Press” or “Press Brake,” this necessary machine tool proceeds to evolve, offering manufacturers enhanced capabilities in precision metal forming and contributing considerably to modern day fabrication procedures.

Thoroughly Welded Building: The body’s entirely welded structure employs advanced welding techniques to deliver Excellent energy and rigidity, minimizing deflection below high loads.

Acquired a project in your mind or will need some qualified suggestions on your subsequent bend? Drop me a line or swing by the shop. We’re usually up to get a chat more than some freshly bent metal!

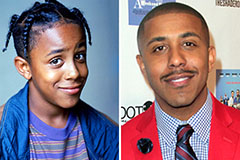

Marques Houston Then & Now!

Marques Houston Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!